Categories

Contact Us

- Add:No.99 ErShengTown, Jurong, Jiangsu, 212432, P.R. China

- Tel:0553-8118891

- Fax:0553-8118891

- Mobile:18505530706

- http://www.reactiveextrusion.com

- Email:sales01@whfsir.com

- Product Details

Product Description:

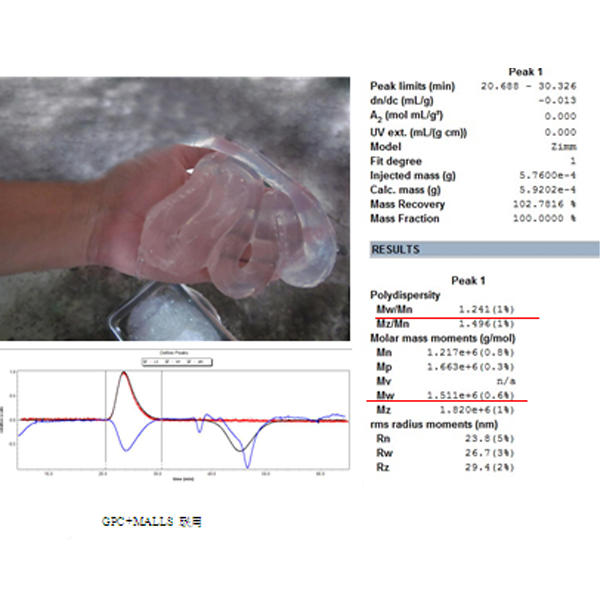

Fluorosilicone compounds are fluorosilicone gums compounded with fillers and additives.

¡¡¡¡ 1:Wide service temperature£¨-60¡«200¡æ£©

¡¡¡¡ 2: Solvent and oil resistance analogous to fluorous rubbers¡¡(FKM)¡¡

¡¡¡¡ 3: Good tensile retention at high temperature.

¡¡¡¡ 4: Fine insulating property

¡¡¡¡ 5: Low gas permeability

Compared with traditional silicone compounds, the advantages of fluorosilicone compounds are its nature of anti-oil, anti-solvent and anti-chemical agents. On the other hand , Fluorosilicone compounds has the similar abilities to anti-alkane solvents as fluorous rubbers.Its aromatic hydrocarbon solvent resistance is even superior to FKM. The suitable solvent for Fluorosilicone compounds is only ketones with high polarities. Soaked in the same medium, time and temperature, the Fluorosilicone compounds also show good durability. The cold enduranceand permanent compression set of FVQM are better than FKM. The FVQM show good properties from low to high temperature and are less temperature dependency. Secondly, FVQM can make low hardness products without adding plasticizer.Therefor the FVQM as a new high performance material are widely used in industry applications.

Characteristic:

Compared with traditional domestic FVQM compound which is roll-sticking and hard to process, our products are easy to handle like imports through special formulas and mixing process. We can also customize the compounds for different applications.

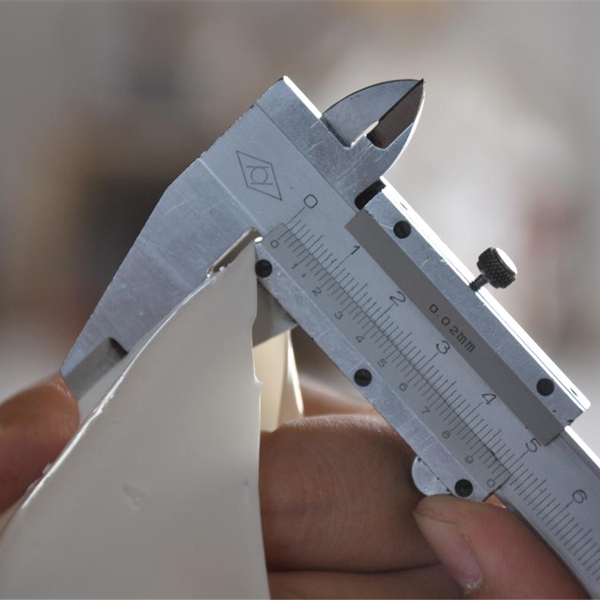

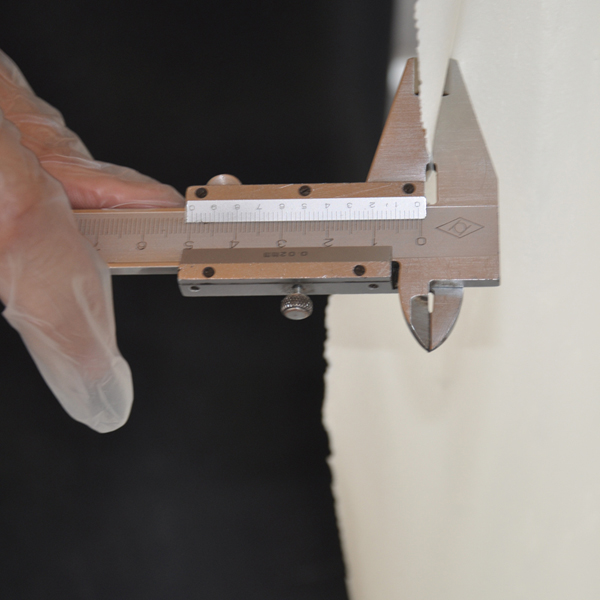

Technical Index:

| FSIR-201 | FSIR-202 | FSIR-203 | FSIR-204 | Testing Methods | |

| Grade | General | ||||

| Hardness shore A | 40¡À2 | 50¡À2 | 60¡À2 | 70¡À2 | ASTM D2240 |

| ensile Strength MPa | ¡Ý7.0 | ¡Ý8.0 | ¡Ý10.0 | ¡Ý10.0 | ASTM D412 |

| Elongation at Break% | 420¡À75 | 400¡À75 | 400¡À75 | 350¡À75 | ASTM D412 |

| Permanent Tensile Set % | 3¡«8 | 3¡«8 | 3¡«8 | 3¡«8 | GB/T528-1998 |

| Tear Strength KN/m | ¡Ý13 | ¡Ý15 | ¡Ý22 | ¡Ý20 | ASTM D624-B |

| Permanent Compression Set 200¡æ 22hr(30%) | ¡Ü20 | ¡Ü22 | ¡Ü22 | ¡Ü25 | ASTM D395 |

| Volume change in Fuel C%(24¡æ¡Á70hr) | ¡Ü25 | ¡Ü23 | ¡Ü20 | ¡Ü20 | ASTM D471 |

Applications:

Aviation, Vehicle, Ships, Electrocommunication, precise instrument, petrochemical industry and Healthy Care.

pack:

Packing with Al compound packing film bag£¬25 Kilograms per bag.

Storage life:

Keep at clean, dry and ventilated environment . Validity : 2 years.

Attentions:Be avoided to contact with acidic and alkaline material before using